CASE STUDY: National Brick Company

The Details

Client

Top Australian Brick Company

Business Area

Transport Optimisation

Industry

Building Material Manufacturer

Location

Australia-wide

Overview

This case study profiles the transport optimisation of a National Brick Company, which is owned by a publicly traded international building material manufacturer. The parent company operates 45 manufacturing plants and 54 design studios globally.

"The solution has brought management, transparency, and consistency as well as increased visibility, efficiency, control, and accountability of our delivery process."

Transport Manager

Business Opportunity

The National Brick Company sought to revolutionise its delivery system to enhance customer satisfaction and operational efficiency. Key business requirements included:

- Fully optimising their delivery system for improved customer service.

- Ensuring all deliveries in a load are completed before new pickups.

- Maximising vehicle capacity for the first load of the day.

- Prioritising heavy orders for early morning delivery.

- Delivering high-priority orders between 7:00 AM and 9:00 AM.

- Implementing fully electronic driver workbooks for safety compliance.

- Tracking drivers in real-time and enabling flexible delivery scheduling.

- Sending customers text notifications with ETAs and delivery confirmations.

- Capturing and sharing live photos as proof of delivery or to flag site issues.

- Minimising unnecessary travel by assigning orders to the same vehicle for a single destination.

- Ensuring efficient pickup and drop-off of additional equipment like forklifts.

- Balancing workloads between core fleet vehicles and contractors to ensure profitability.

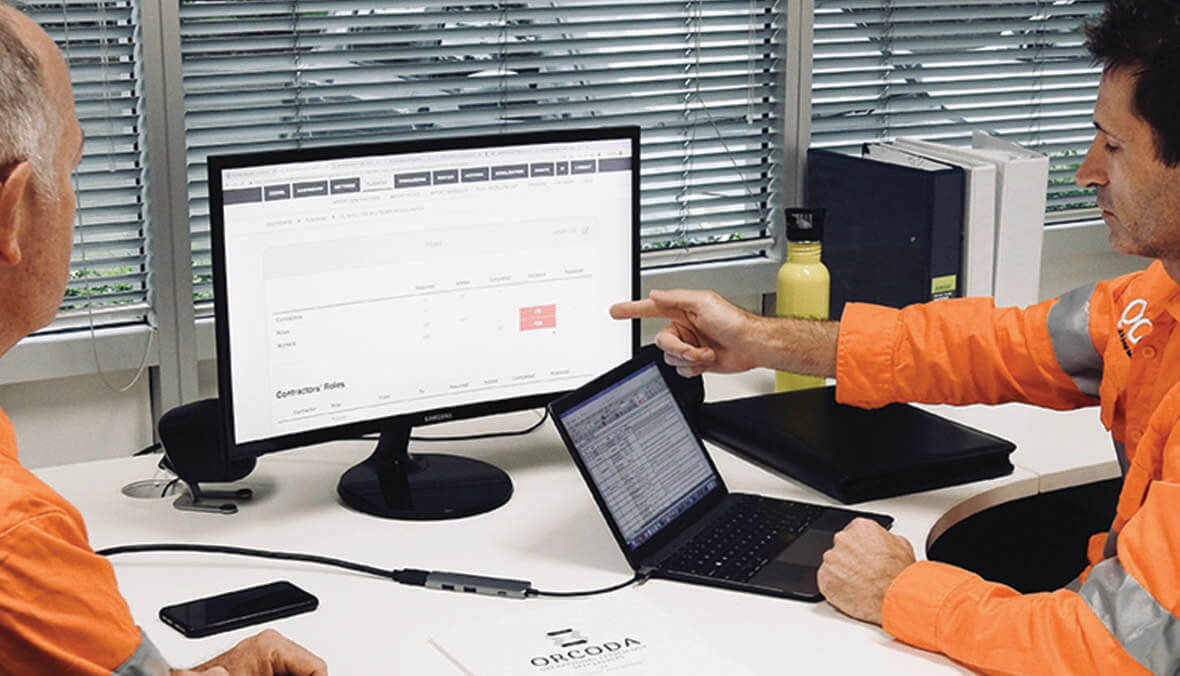

Solution

- Batch Loads: The system ensured that deliveries within a load were completed before new pickups, maximising vehicle capacity and eliminating underutilised loads.

- Driver Tracking & Scheduling: Enabled real-time tracking of drivers and flexible scheduling processes, improving visibility and control over daily operations.

- Electronic Driver Workbooks & Compliance: Drivers were equipped with fully electronic workbooks, ensuring improved safety compliance and verification.

- Customer Communication: Automated text notifications were sent to customers, providing ETAs for deliveries and confirmations upon completion. Photos were captured as proof of delivery or site issues, viewable in real-time.

- Zoning & Load Efficiency: The system optimised load allocations by zoning deliveries to prevent unnecessary travel, prioritising core fleet vehicles for efficiency.

- Proof of Delivery: Drivers could upload photos as evidence of successful delivery or to flag any issues at the site.

The solution provided National Brick Company with a more efficient and customer-friendly service while delivering greater transparency and control over their delivery process.

Outcome

After implementing Transport360, the National Brick Companysignificantly improved its delivery efficiency and overall customer experience.

- Enhanced customer service with real-time ETAs and delivery confirmations.

- Fully electronic driver workbooks, improving safety compliance and process verification.

- Greater visibility into the delivery process, leading to more efficient and customer-friendly service.

- Proof of delivery with photos, improving transparency and accountability.