The True Cost of Operational Efficiency:

What the Best-Run Logistics Teams

Do Differently

Written by Simon Anthonisz, General Manager of Transport at Orcoda.

Razor-thin margins, rising fuel and asset costs, and the daily headache of complex scheduling are now daily realities for fleet managers. You’re not alone. The true cost of operational inefficiency goes far beyond the balance sheet. It’s measured in missed delivery windows, underutilised assets, frustrated staff, and a weakened competitive edge.

The challenge for many transport and logistics leaders is translating efficiency goals into meaningful, measurable results across their fleets, schedules, and systems.

At a recent webinar, “The Real Cost of Operational Efficiency and What the Best-Run Logistics Teams Are Doing Differently,” industry leaders dove deep into these issues. The consensus was clear: the old ways of working are no longer enough. The best-run logistics teams aren’t just working harder; they’re working smarter by leveraging technology, data, and a new way of thinking about optimisation. This blog captures the key takeaways from that session, including a powerful case study from Australian logistics giant Northline, to give you actionable strategies for transforming your operations.

The Pressures Piling on Modern Logistics

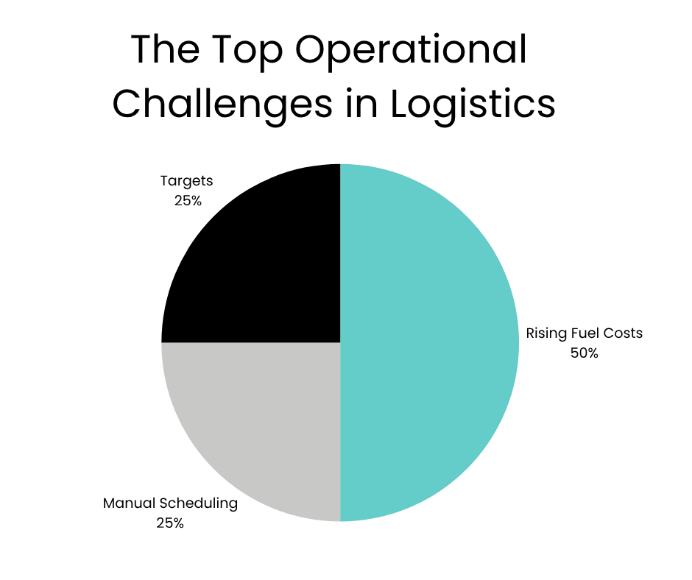

The challenges facing the supply chain today are multifaceted. It’s a perfect storm of economic pressure, resource scarcity, and evolving customer expectations. In a live poll during our webinar, we asked attendees to name their single biggest operational challenge. The results were revealing:

- 50% identified rising fuel and asset costs as their top concern.

- 25% pointed to manual scheduling and paperwork.

- Another 25% were focused on meeting sustainability targets.

These aren’t just isolated problems; they are deeply interconnected. Inefficient, manual scheduling leads to more kilometres driven, which in turn drives up fuel costs and makes sustainability goals harder to hit. This is the true, compounding cost of operational efficiency: where a weakness in one area creates expensive problems in another. Adding to this are challenges with an aging workforce, the complexities of the gig economy, and the need to transition to alternative fuels.

Moving Beyond Tribal Knowledge: The Secret of the Best-Run Teams

So, how are the best-run teams overcoming these pressures? They’re making a fundamental shift away from a reliance on “tribal knowledge,” the experience-based, gut-feel decisions of dispatchers and drivers, to a model built on system intelligence.

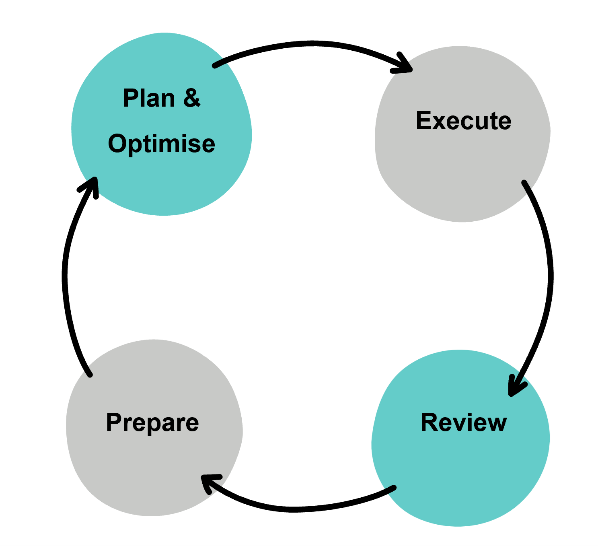

This is the core of what we call the Theory of Effective Optimisation. It’s not just about finding the shortest route. True optimisation aligns every component of your operation, people, vehicles, schedules, and systems, to work in perfect harmony. It’s a continuous, dynamic cycle:

- Plan & Optimise: Build the most efficient schedule possible by mathematically analysing all constraints: weight, volume, driver hours, fatigue rules, and more.

- Execute: Deliver the plan with real-time visibility, allowing you to adapt to dynamic conditions like traffic or last-minute changes.

- Review: Assess the outcomes of the plan against reality. Did you meet your targets? Where were the deviations?

- Prepare: Feed that data back into the system to refine and improve the next day’s plan, creating a cycle of continuous improvement.

This four-step loop transforms optimisation from a one-off task into the living, breathing heart of your operation, constantly adapting and improving efficiency, cost, and service.

From Theory to Reality: How Northline reduced its required fleet by an average of 10% per branch.

To illustrate the power of this approach, we were joined in the webinar by Adam Woods, National PUD and Business Improvement Leader at Northline, a major Australian transport and logistics company.

The Challenge: Trapped by Legacy Systems

Five years ago, Northline faced a common challenge. Their legacy system, while functional, offered limited visibility and transparency over fleet management. The planning process was manual, time-consuming, and heavily reliant on experienced staff. As Adam explained, “The old system didn’t have a lot of visibility or transparency and could not review driver performance”. With metro areas expanding and kilometres travelled increasing, they needed to find a way to maintain and improve cost efficiencies.

The Solution: A Data-Driven Foundation for Growth

Northline embarked on an improvement journey, implementing Orcoda’s

Transport360, overhauled the PUD operations for Northline. Their focus was squarely on route optimisation as the key to unlocking efficiencies.

The results have been transformative. By embracing data-driven planning,

Northline reduced its required fleet by an average of 10% per branch..

Adam noted, “The standout benefit of Transport360 is finding out the cost efficiencies, then being able to analyse those cost efficiencies, and then put it into action”. Transport360 provided the tools to move beyond guesswork. “It’s a tool to do better planning. It’s a tool to get the best route. It’s a tool to be able to fleet manage”.

This new level of visibility allows them to understand driver activity, manage workloads, and significantly reduce planning time. While implementation required significant change management, Adam sees the platform as a foundational system for future growth. “We’ve got something now that we can use as a foundation system where we can just keep building on it”.

Key Takeaways for Your Operation

Northline’s journey provides a blueprint for improving operational efficiency in logistics. Here are three key strategies you can apply to your business:

- Prioritise Asset Utilisation: In our webinar poll, a massive 63% of attendees identified “Optimising Asset Utilisation” as their key focus for increasing efficiency. This is where the biggest gains are found. True optimisation ensures that every vehicle in your fleet is carrying the ideal load on the most efficient run, maximising its value every single day.

- Embrace Data-Driven Decision Making: As Adam from Northline stated, the new technology gave them “more data for us to analyse, and that’s where we get the increased transparency and visibility”. This data allows you to model different scenarios, analyse performance, and make strategic decisions about your operational model, rather than just tactical ones. For further reading, the Australian Government’s Bureau of Infrastructure and Transport Research Economics (BITRE) provides extensive data on road freight movements and costs.

- Build a Foundation for the Future: The industry isn’t standing still. The push for AI integration, electric vehicles, and more complex fleet models (mixing owned, subcontracted, and outsourced assets) is accelerating. As Northline is now doing, leaders must look to what’s next, including AI. Implementing a flexible, powerful transport management solution today provides the foundation you need to adapt and thrive tomorrow. A recent report by McKinsey highlights how AI and automation are becoming critical for competitive advantage.