CASE STUDY: Shutdown for Leading Australian Mining Company

The Details

Client

Leading Australian Mining Company

Business Area

Contractor360

Industry

Mining

Location

Australia

Overview

Orcoda worked with Minset to provide the Contractor360 solution for the Mine Shutdown of one of Australia’s leading mining companies.

Minset is a business improvement service provider specialising in fast-tracking performance enhancements for its clients by integrating digital solutions with site teams.

“We are excited to be partnering with ORCODA to implement their digital products to optimise shutdowns across mines that we work on. We know this is an important evolution in improving shutdown performance across the resources industry, and we were impressed at the ORCODA Management System digital platform’s ability to deliver the outcomes required to improve efficiency on a recently completed shutdown project.”

Andrew Attrill, Director, Minset

Business Opportunity

Site teams on this major mine site had been manually managing workforce logistics data. Data was also housed in multiple, disconnected places, making communication and monitoring by site stakeholders a challenge. The result was time-consuming and error prone work. To increase logistics efficiency, Orcoda’s digital platform was selected by business improvement consultancy, Minset, as the leading resources-specific solution with the best breadth of workforce management functions. Orcoda was introduced to support a step change in workforce logistics management as part of an intensive new shutdown management framework led by Minset.

Solution

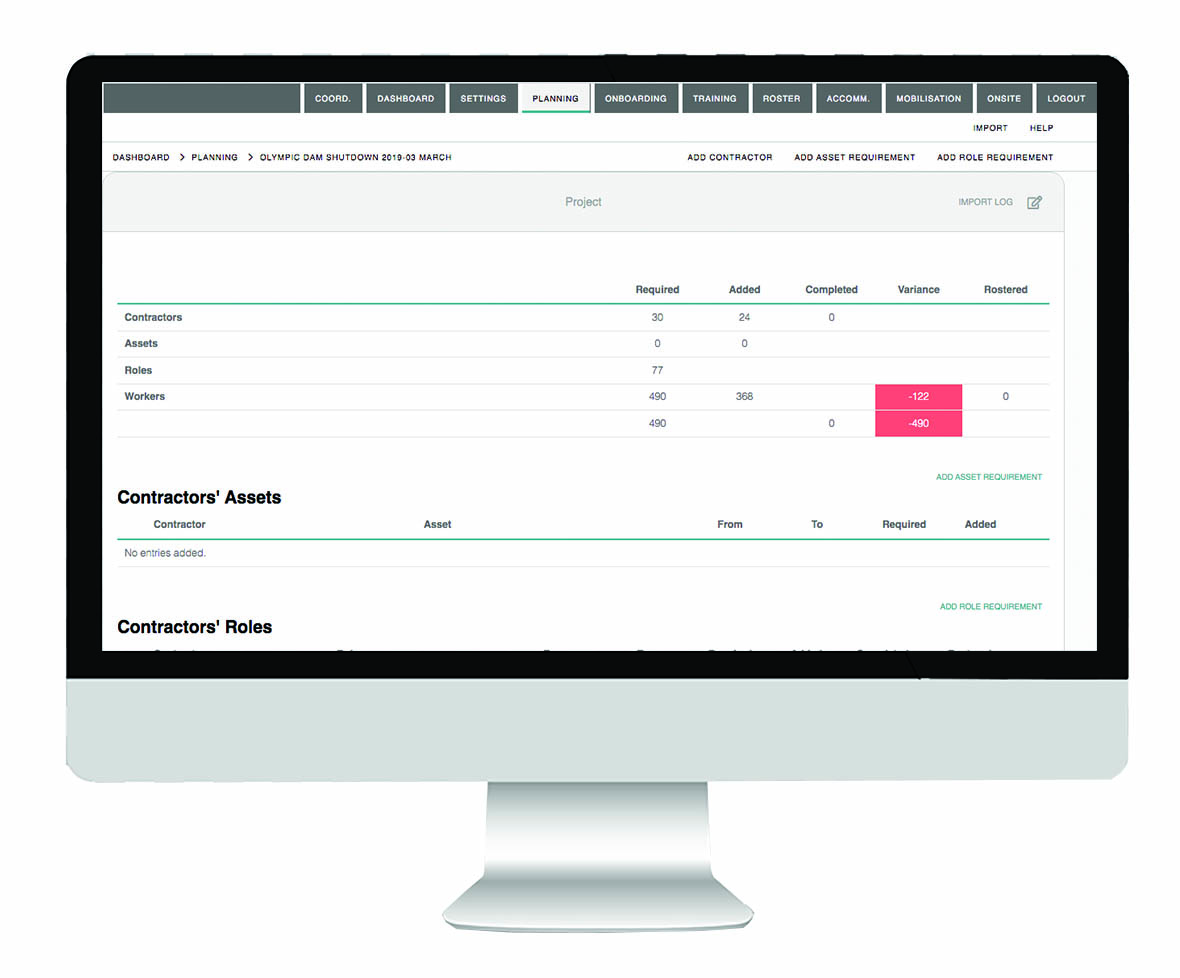

Orcoda worked with Minset and the client to develop a bespoke version of Contractor360 that specifically considered their challenges – identifying pain points, understanding workflows and learning about existing systems (in-house and third party) to tailor the solution. Contractor360 was set up as ‘middleware’ that could manage data using existing system language so that databases could be easily shared between site and external parties. Using agile methodology (ie incremental development), the bespoke software grew in line with the client’s needs. The system was also implemented in two phases to reduce risk and maximise the identification of improvement opportunities: first as a partial trial in parallel with client systems, and second as the primary workforce logistics management system used in a full shutdown environment.

Outcome

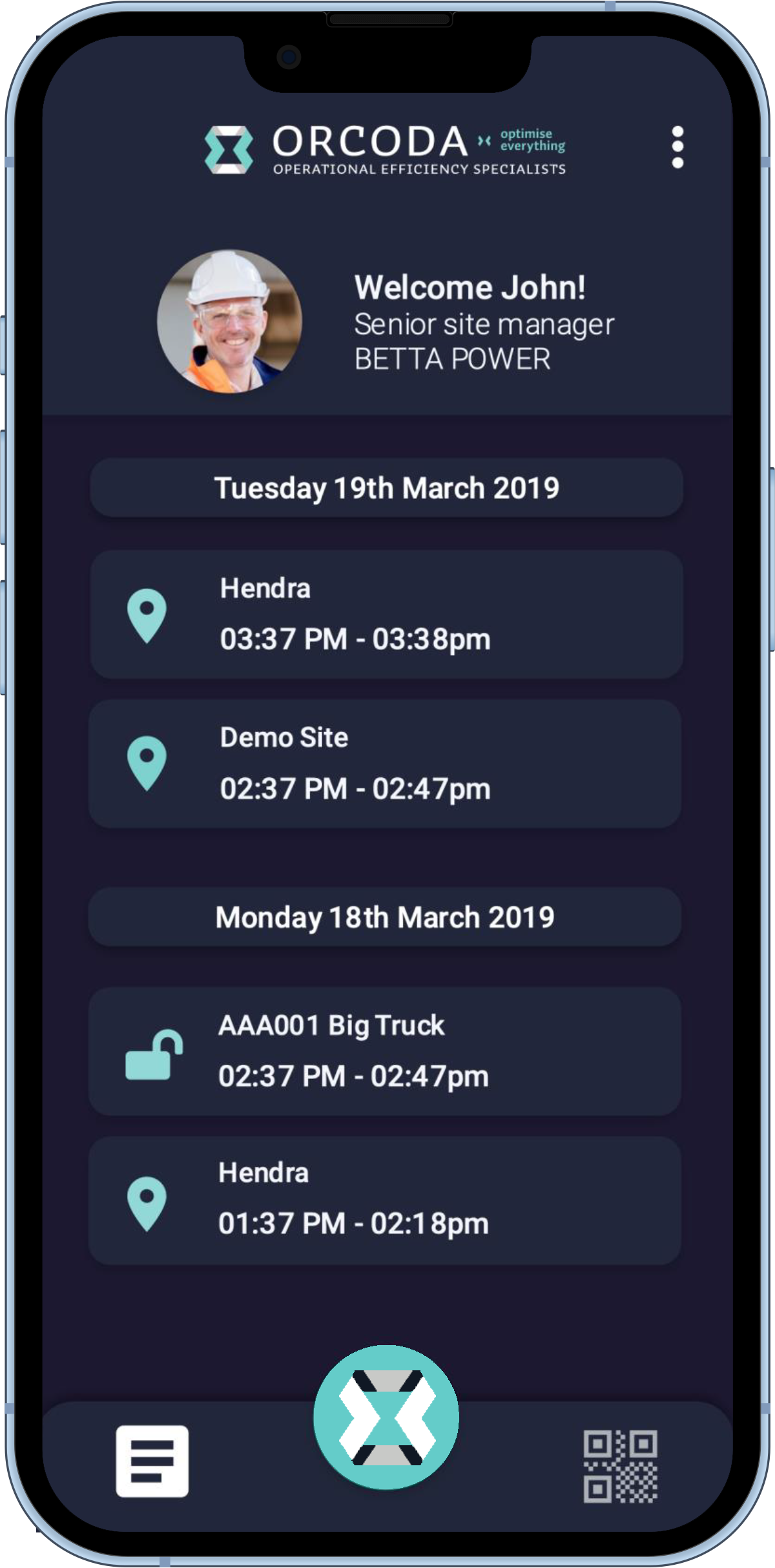

- Managed 91% of workforce data (30 contractors and 367 workers and assets) via automated workflows. Reduced administration time and effort, as well as manual handling errors

- Gave greater ownership to each division for their workflows by removing ‘linear’ dependencies (ie giving them the ability to work incrementally as data became available)

- Enabled live workforce compliance through automated updates (eg accreditation, qualifications, competencies)

- Improved safety outcomes by fast-tracking identification of training and induction gaps

- Enabled streamlined data exports to third party suppliers

- Supported broader improvements in site work methods through the discovery and implementation process

- Created a foundation for future process improvement including application beyond shutdowns

- Created future efficiency with workforce data able to be rolled over to other projects