Why Smart Technology

is No Longer Optional

“Transport is the backbone of the Australian economy, moving over 800 billion tonne-kilometres of freight annually, and yet, inefficiencies are costing us over $5 billion every year.”

::: Infrastructure Australia, Freight & Supply Chain Strategy

Australia’s logistics and transport sector is currently undergoing a significant transformation. Rapidly evolving consumer expectations, rising environmental responsibilities, and the complexity of delivering services across a vast geography have exposed deep inefficiencies in traditional logistics models. The need for smart, scalable, technology-driven solutions is no longer theoretical. It is now fundamental to operational survival.

At Orcoda, we are at the heart of this transformation.

From workforce optimisation to intelligent transportation scheduling and infrastructure logistics, our technologies are helping clients digitise and streamline their most complex operations. This article explores why the future of logistics in Australia is inextricably tied to technology and why action is needed today.

Inefficiency is a multi-billion-dollar problem

Legacy logistics processes, often spreadsheet-based or reliant on siloed systems, are costing the Australian economy dearly. A 2023 PwC report estimated that inefficiencies in transport and freight lead to over $5 billion in annual economic losses, primarily due to delays, idle time, duplicated tasks, and poor visibility.

Manual systems can’t keep up with modern logistics demands. Whether it’s coordinating hospital transport across a health district or managing asset movements on a construction site, the absence of real-time data leads to overbooking, under-utilisation, and scheduling chaos.

Orcoda’s platform directly addresses these issues. For example, in our work with government clients managing assisted transport services, we’ve improved on-time performance by up to 35%, reducing vehicle kilometres travelled and cutting emissions. This level of visibility and efficiency isn’t possible without deeply integrated smart software.

Technology adoption is well underway … But it is uneven

Forward-thinking organisations across Australia are no longer sitting on the sidelines. They are actively implementing innovative logistics technologies and experiencing transformative results.

From mining giants and infrastructure contractors to health transport providers and major retailers, the shift towards digital platforms is delivering more than just incremental improvements. These businesses are unlocking unprecedented efficiency, visibility, and operational control. They’re cutting costs, reducing emissions, enhancing compliance, and staying agile in an increasingly competitive environment. What was once considered an optional upgrade has become a strategic imperative. In today’s fast-moving logistics landscape, smart technology isn’t a future ambition. It’s a present-day advantage.

Consider the following recent examples:

- Coles has invested more than $1 billion in advanced robotic fulfilment centres in Redbank (QLD) and Kemps Creek (NSW), dramatically improving the speed and accuracy of order handling.

- Amazon has scaled its Australian infrastructure to 6 fulfilment centres and 12 logistics hubs, using real-time data and robotic automation to process thousands of orders per hour.

- Aurizon, the nation’s largest rail freight operator, is deploying predictive analytics to optimise maintenance schedules and reduce unplanned downtime.

- Linfox uses telematics and route optimisation to reduce emissions by 20% on select routes, improving customer service and sustainability.

- Australia Post has committed to introducing electric delivery vehicles in urban areas, responding to growing pressure for carbon-neutral logistics.

Even mining companies are taking the lead in this initiative. Fortescue Metals Group has adopted autonomous haulage trucks in Pilbara operations, demonstrating how automation improves safety and productivity in remote logistics environments.

Yet despite these successes, many mid-sized operators remain hesitant. Some cite cost. Others point to integration complexity or internal resistance to change. But as we’ll explore next, these are surmountable challenges.

Barriers to adoption …

And how to overcome them

One of the common barriers to technology adoption in logistics is the fear of disruption. For many operators, especially in the field service or infrastructure sectors, legacy systems and processes are deeply entrenched. Change can feel risky, especially when core service delivery is at stake.

However, we often see that not changing is riskier. Inefficiencies compound over time, labour shortages intensify, and compliance breaches become more likely. Most critically, competitors who digitise gain faster, cheaper, and more scalable operations.

The second barrier is cost. However, it’s important to reframe this as an investment. The return on smart logistics software is measurable. At Orcoda, we’ve seen clients cut operating costs by 10–25%, reduce fleet downtime, and improve workforce utilisation significantly within the first year.

Finally, integration anxiety holds many back. But modern platforms like Orcoda’s are designed to be modular and interoperable. We work closely with clients to integrate with their existing systems, provide training, and ensure a smooth transition with minimal business disruption.

The Australian government is backing the shift

The Australian government is increasingly recognising that smart logistics is essential for national productivity. The National Freight and Supply Chain Strategy explicitly prioritises “better planning and coordination” and “smarter infrastructure.”

The federal government’s National Freight Data Hub, currently in rollout, aims to provide real-time data sharing across the supply chain ecosystem. This kind of digital infrastructure will become a baseline requirement for accessing funding, managing compliance, and competing effectively.

Additionally, Infrastructure Australia has called for digital engineering to be embedded in all major projects by 2025. Logistics and workforce platforms that provide audit trails, predictive analytics, and live tracking are already proving critical in meeting these requirements.

Smart technology is the key to sustainability

The logistics sector accounts for about 9% of Australia’s total greenhouse gas emissions, with freight transport (especially road freight) a major contributor. As companies align with ESG frameworks and sustainability targets, digital technology is proving essential.

Smart logistics systems allow routes to be optimised, idle times reduced, fleet loads balanced, and unnecessary trips eliminated. Even small changes, like consolidating dispatch windows or avoiding peak traffic, can reduce emissions by 10–15%.

At Orcoda, our clients often begin with a cost-efficiency brief but quickly realise the environmental benefits of our platform. These aren’t just compliance wins—they’re also powerful brand and customer value drivers.

Orcoda’s role in leading Australia’s logistics transformation

Orcoda is uniquely positioned to help Australia digitise its logistics sector. Our platforms span multiple industries, including health transport, infrastructure projects, and commercial logistics. It is pertinent to note that our platforms are built for the real-world complexity of Australian operations.

What sets us apart is our vertical integration of transport, workforce, and asset management. This allows clients to coordinate complex operations with a single source of truth, eliminating silos, reducing admin overhead, and improving decision-making in real-time.

In Queensland, our work with major road and rail contractors is helping deliver billion-dollar infrastructure projects on time and on budget. We support health transport operators managing vulnerable passenger movements with real-time scheduling and incident alerts. Across remote regions, we’re helping mining and resource companies coordinate workforces, vehicles, and compliance, all on one platform.

Our solution isn’t theory. It’s proven: live, operational logistics made smarter through technology.

The future is already here …

Don’t get left behind

The transformation of Australia’s logistics industry is well underway. The next phase will separate those who are ready from those who are not.

Technology adoption is no longer optional. It’s the price of entry into a logistics environment that demands speed, safety, transparency, and sustainability. Organisations that embrace this shift will thrive. Those who resist will struggle to compete.

At Orcoda, we believe the path forward is clear, and we’re here to help lead the way.

Conclusion: A sector on the brink of breakthrough

Australia’s logistics sector is no longer inching towards a digital future. We are now accelerating into it. As this blog has shown, smart technology is not just solving operational challenges; it’s reshaping how freight, infrastructure, and field services are delivered across the country. The costs of inefficiency are too high, the environmental stakes too urgent, and the customer expectations too elevated to ignore. Whether you’re in public health, infrastructure, or commercial transport, digitisation is a competitive advantage. The future of logistics isn’t coming. It is already here. And those who embrace it will lead.

Next Steps: Unlocking value with Orcoda’s Transport360

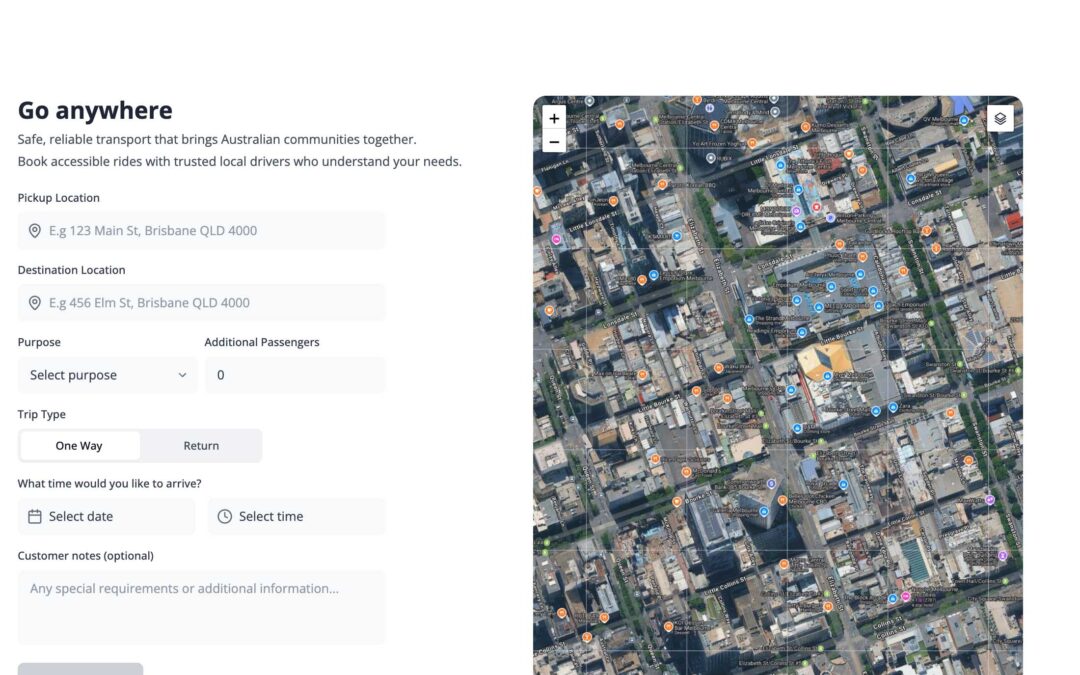

If you’re ready to digitise your operations, the next step is clear: Transport360.

Transport360 is a powerful, modular platform designed to simplify complex logistics, from workforce scheduling and route optimisation to asset tracking and compliance. Built specifically for Australian conditions, Transport360 integrates transport, field operations, and data analytics into a single source of truth, giving you the visibility, control, and efficiency you need to scale.

Whether you’re coordinating large infrastructure projects, managing sensitive transport services, or running high-volume logistics, Transport360 delivers measurable results. Faster delivery, fewer emissions, lower costs, this is logistics done smarter. Let’s make it happen.